Jeep Parts Wiki | Ford Parts Wiki

Home | Search | Browse

|

Corvette Assembly Manual January 1978 |

|

Prev

Next

Next

1740857

1740857

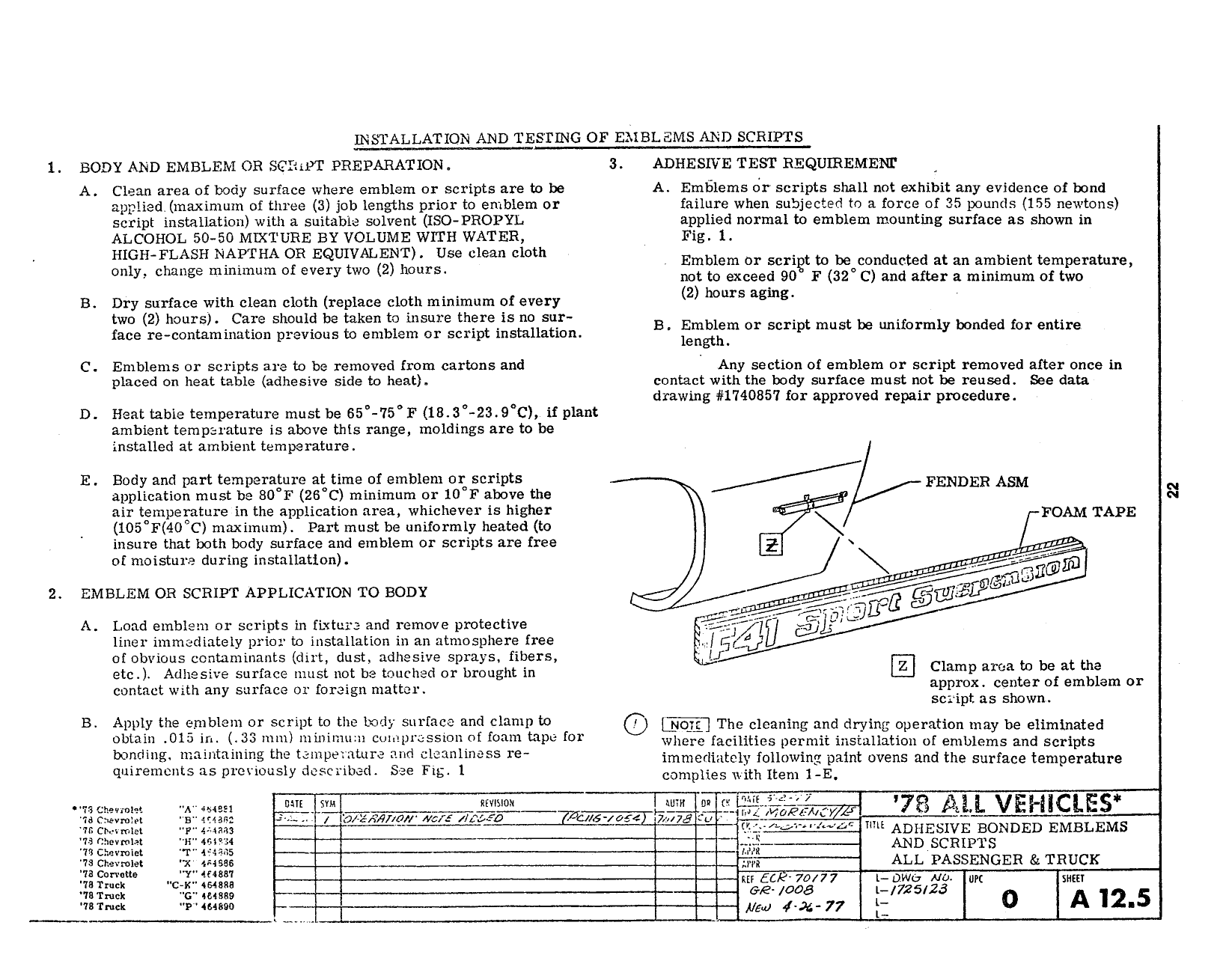

INSTALLATION AND TESFING OF EMBLEMS AND SCRIPTS 1 BODY AND EMBLEM GR SGIiil T PREPARATION 3 ADHESIVE TEST REQUIREMENT A Clean area of body surluce where emblem or scripts are to be A EmElems or scripts shall not exhibit any evidence of bond applied maximum of three 3 job lengths prior to emblem or failure when subjected to a force of 35 pounds 155 newtons script installation with a suitable solvent ISO PROPYL applied normal to emblem mounting surface as shovlm in ALCOHOL 50 5i0 1vlD TURE BY VOLUME WITH WATER Fig 1 gse 1 l h Emblem or script to be conducted at an ambient temperature not to exceed 90 F 32 C and after a minimum of two B Dry surface with clean cloth replace cloth minimum of every 2 mus aging two 2 hours Care should be taken to insure there is no sur face re contamination previous to emblem or script installation B 5 m S be Y b d d C Emblems or scripts are to be removed from cartons and Any section of emblem or script removed alter once in placed on heat table adhesive side bo heat contact with the body surface must not be reused see data drawing 1740857 for approved repair procedure D Heat table temperature must be ss 7s 1 1a a 2a s c lf plant ambient tem perature is above this range moldings are to be installed at ambient temperature E Bvdy and part temperature at time or emblem gr scripts D application must be s0 F 26 c minimum or 10 F above the FEN LR ASM S air temperature in the application area whichever is higher FOAM TAPE 105 F 40 C maximum Part must be uniformly heated to insure that both body surface and emblem or scripts are free Z e of moisture during installation z ue 2 EMBLEM OR SCRIPT APPLICATION TO BODY 2 4KpQ J gi e Z 1 g J A Load emblem or scripts in fixture and remove protective 12 i liner immediately prior to installation in an atmosphere lree gkjjy oiobvioos contaminants dirt dust adhesive sprays fibers if etc Adhesive surface must not be touched or brought in El Clamp me b at the contact with any surface or foreign matter aPl X t emblem script as shown B Apply the enibleni or script to the Lmdy surtace and clanip to Liu The clnnning and Gwinn Onernunn may be eliminated obtain 01o in nas uiuil niniiiniitii cui pi essioii oi loam tape lor Wnnw fncmuns nnrmn instnnnmn of emblems and Scripts bonding inuintuiiiing the teinpezritiire and cleanliness re n nn n nntnn munwinn paint Ovens and me Surface temnemhue quirements as previously deserilvctl See Fig l cnmnnes with Hem 1 E new 4 E multi tum iu V F mer 2 No s a E ee V 78 itc e ei i ny4 we T t Aplieslvla BONDED EMBLEMS va e lt W w K i ncn et t ra con T an AND SCRMS uei nai t nr mot Il pm ALL mssezmcpn at TRUCK pacomite w tum jj j ELK70 77 l DW No Z FZ Gel 005 725 25 Mw 77 it

Next

Next