Jeep Parts Wiki | Ford Parts Wiki

Home | Search | Browse

|

Corvette Assembly Manual January 1978 |

|

Prev

Next

Next

9981293

9981293

9981062

9981062

3072504

3072504

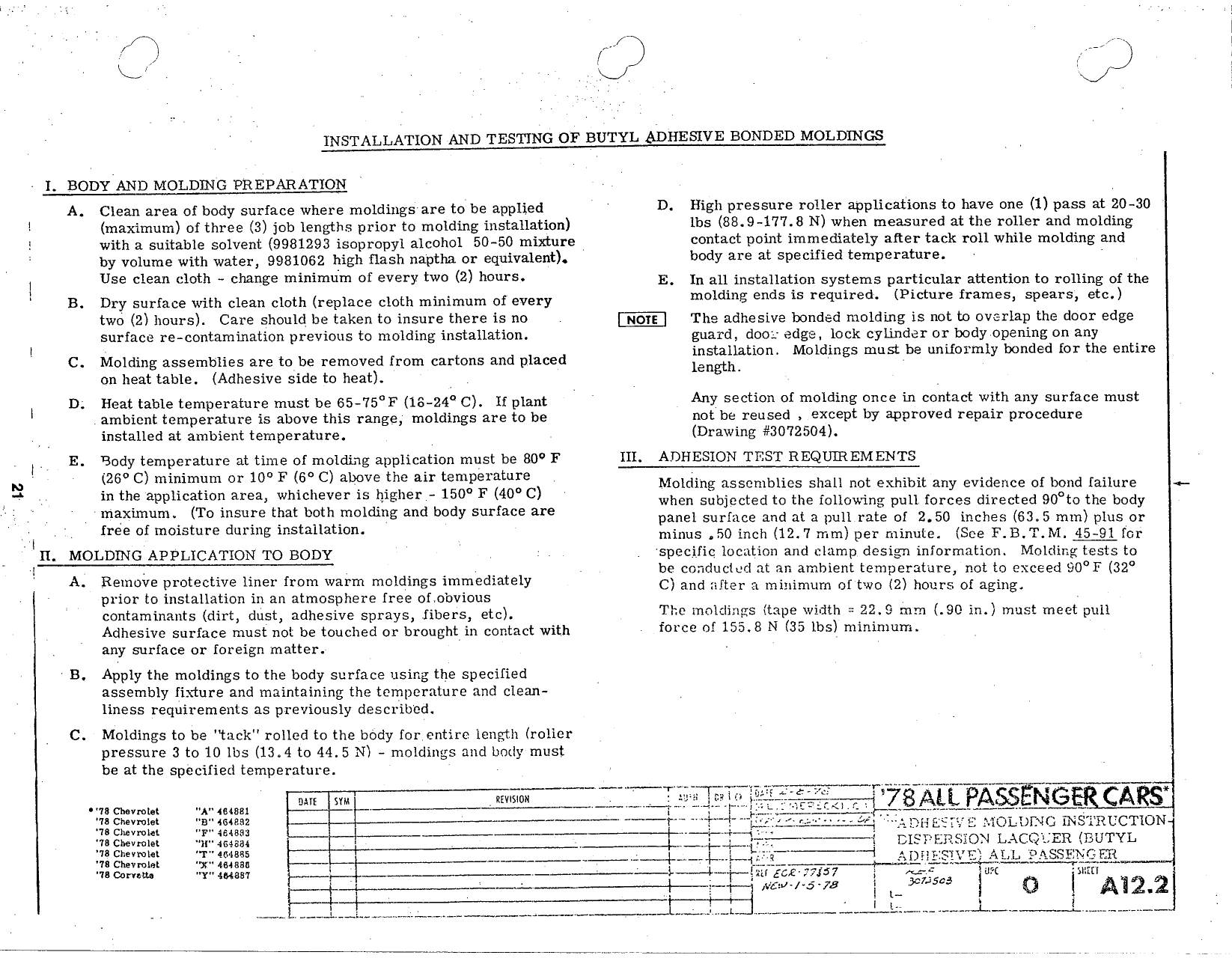

I j 1 I INSTALLATION AND TESTING OF BUTYL ADHESIVE BONDED MOLDTNGS I BODY AND MOLDING l REl A RATl0N A Clean area oi body surface where moldings are to be applied D High pressure roller applications to have one 1 pass at 20 30 maximum or three 3 job lengths prior to molding installation lbs 8B s i lv s N when measured at the roller and molding e with a suitable solvent 9981293 isopropyl aleohol 50 50 mixture contact point immediately alter taelt roll while molding and by volume with water 9981062 high flash naptha or equivalent body are at specified temperature I Use le n elelh elnnse minimum f every lwe 2 l r lz In all installation systems psi tleuler attention to rolling or the B Dry surface with elean cloth replace eloth minimum or every meldlns ends ls required P cture frames spears ete two 2 hours Care should be taken to insure there is no The adhesive bonded mcldin is not to overlap the door edge 2 surface reseontamination previous to molding installation guard doo edge lock cylinder or body opening on any c Molding assemblies are to be removed from cartons and placed Q M d gS St be i xY bowed me 0n heat table Adhesive side to heat i D neat table temperature mnst be ss 7s F ls 24 c ll plant Any section el rneldlns ence in contact with any surface must ambient temperature is above this range moldings are to be not be reused except by approved repair procedure installed at ambient temperature Drawing 3072504 I E Body temperature at time of molding application must be 0 F lll ADHESION TEST REQUIREMENTS rg I26 CI T wu F I6 C F E Yhc m h i0 dihg assemblies shall not exhibit any evidenee of bond lailure in the applieation area whiehever is higher 150 F 40 C 0 T th t b th mi d b d I a 8 when subieeted to the tollondng pull forces directed 90 to the body S F F Y S me panel surface and at a pull rate or 2 50 inches 6 s s mm plus or I free of moisture during installation minus 50 inch 12 1 mm pei minute See F B M 45 91 lor A IL MQLDING AppL CATl0N TO BODY specific loolltion and uml np design information Molding tests to li R m V t Y ld m diatgl be conducted at an ambient temperature not to exceed oo lr zz V o pro er ive rnel rom warm m0 mgsl nre Y 0 and after zi minimum ol two 2 hours of aging prior to installation in an atmosphere free ofoovlous oontaminants dirt dust adhesive sprays fibers ete The 9l l i l e Wl lll 229 90 ind must meet pull Adhesive surface must not be touched or brought in contact with rerce nl 155 8 N 3 lbs rninirnum any surface or foreign matter B Apply the moldings to the body surface using the speeilied assembly fixture and maintaining the temperature and clean liness requirements zis previously described c Moldings to be ttiek rolled to the body lor entire length roller pressure 3 to 10 lbs 13 4 to 44 5 N moldings and body must be at the speeiiied temperature t T QZQTIQTY F Ch Y k www tm site i l s 4 s I l I j t i 2i a no nn l nr loom t Q ria HL E E r l0Ll lNG 4S l RlJCTl0N ii einrnuei r tron 1 III jiecrevnnei i 4tteil L m i l lSw nsi0 l L CQi ER BUTYL 3 g g gggggg 1 r4 i f if tQ i H l L 1 W EY 5 mmm Y mm Y j fill gee 7157 l F5 ll7 will ter we I 0 I A12 l r sr J L

Next

Next