Jeep Parts Wiki | Ford Parts Wiki

Home | Search | Browse

|

Corvette Assembly Manual January 1978 |

|

Prev

Next

Next

9981293

9981293

9981062

9981062

9981801

9981801

9981801

9981801

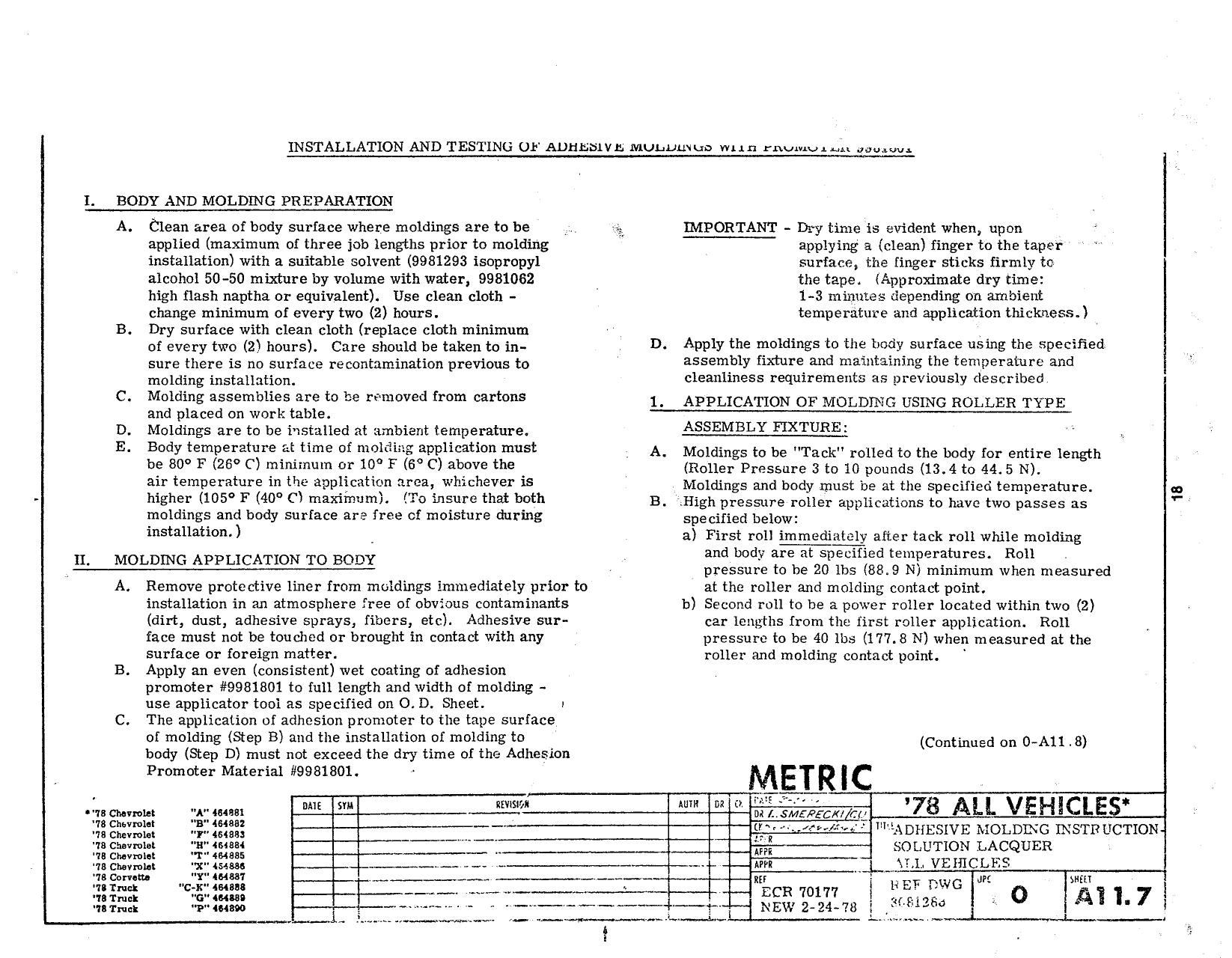

INSTALLATION AND TEs 1 lNu ul Aumsslvr munobvoe will i rr o o r ssoswl 1 BODY AND MOLDlNG PREPARATION A Clean area of body surface where moldings are to be HVIPORTANT Dry time is evident when upon applied maximum of three ich lengths prior to molding applying a clean finger to the taper installation with a suitable solvent 9981293 isopropyl surface the finger sticks firmly to alcohol 50 50 mixture by volume with water 9981062 the tape Approximate dry time high flash naptha or equivalent Use clean cloth 1 minutes depending on ambient change minimum of every two 2 hours temperature and application thickness B Dry surface with clean cloth replace cloth minimum of every two 2 hours Care should be taken to in D Apply the mpldlnes the l v svrfepp using the sp i e l sure there is no surface recontamination previous to assembly li s l l l l l i s lhs tsplperalprv and molding i smmuOn cleanliness requirements as previously described C Molding assemblies are to be removed from cartons L APPLICATION OP MOLDTNO USING ROLLER TYPE and placed on work table t D Moldings are to be installed at ambient temperature E Body temperature at time of molding application must A Moldings to be nTack rolled to the body kn Enum length be F 2s Cl i i r 10 F 6 C allpvs lhs O Roller Pressure a to l0 pounds 13 4 to 44 5 N air lemperalure in lhs application arpa Whichever ls Moldings and body must be at the specified temperature P higher 105 F 40 C mrurimuml To insure fha bvfll B l ligh pressure roller applications to have two passes ns moldings and body surface are free cf moisture during spgcmed below installation al First roll immecli y after tack roll while molding and body are at specified temperatures Roll pressure to be 20 lbs aa N minimum when measured A Remove protective liner from moldings immediately prior to at the roller and molding contact point installation in an atmosphere free of obvious contaminants b Second roll to be a power roller located within two 2 dirt dust adhesive sprays fibers etc Adhesive sur car lengths from the first roller application Roll face must not be touched ol brought in contact with any pressure to be 40 lbs 177 8 N when measured at the surface or foreign matter roller and molding contact point B Apply an even consistent wet coating of adhesion promoter 9981801 to full length and width of molding use applicator tool as specified on O D Sheet i C The application of adhesion promoter to the tape surface of molding Step B and the installation ol molding to cnnunngn on 0 Au B body Step D must not exceed the dry time of the Adhesion Promoter Material 9981801 i iiliilil m E it M sise v ie 78 LLL VLHLCLE m n n 8 1 r f 1 jg M Anlllaslii L MOLDl G INSTRUCTION ili mlzt 22 253 Q rr T LACQUER q noi 1 a im L g l VEIHCLRS l o r i em in N in mu g 1 We s sen vom l F EK NG 9 A1 7 1 2 p mm X q Nzw 2 zivltl i 2 l Y l i e c s l

Next

Next