Jeep Parts Wiki | Ford Parts Wiki

Home | Search | Browse

|

Corvair Assembly Manual December 1964 |

|

Prev

Next

Next

3862100

3862100

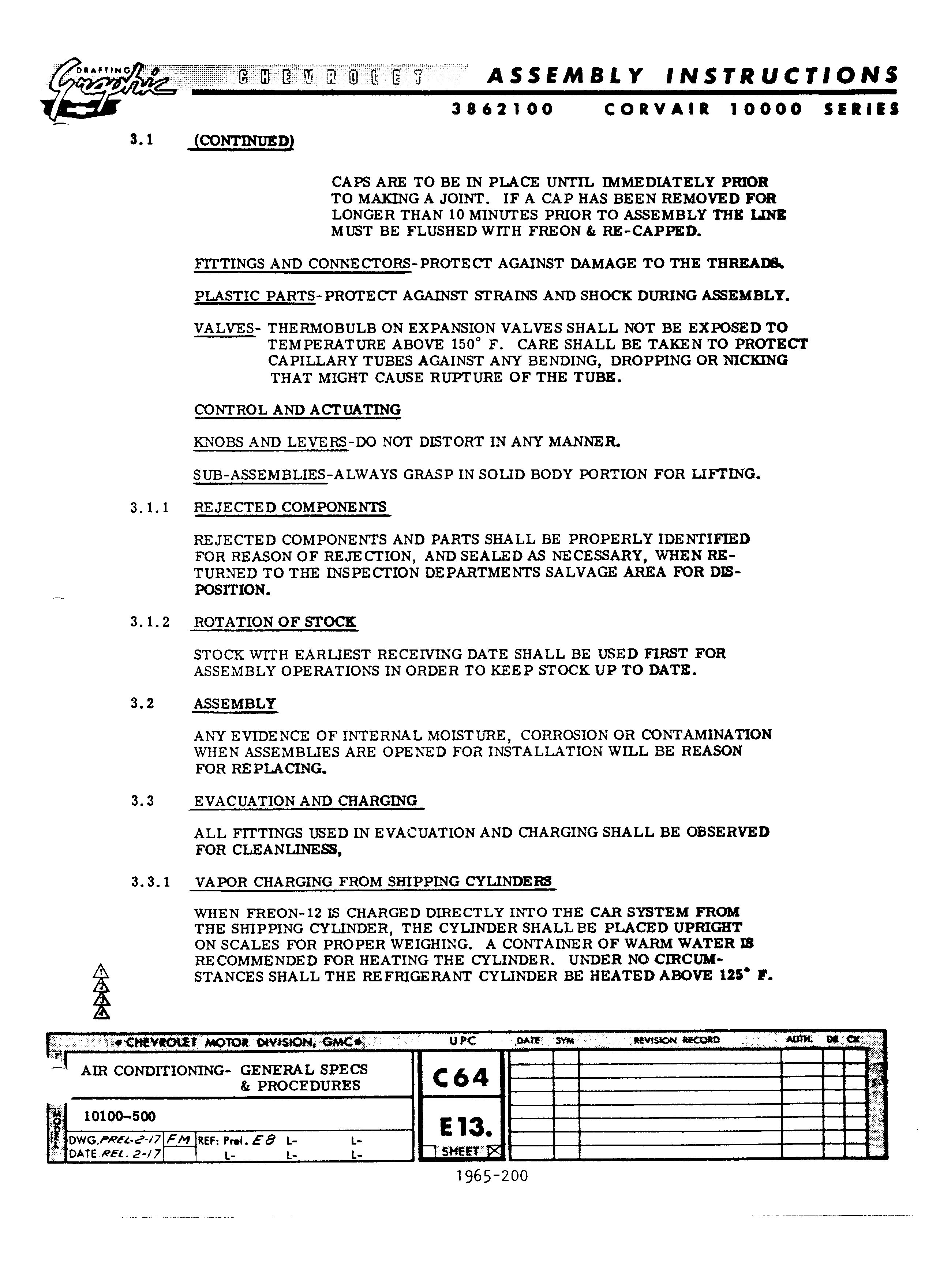

I A S S E M B L Y I N s T R U c Tl 0 N S I 3862100 CORVAIR 10000 SERIES 3 1 SCONTINUEDQ CAPS ARE TO BE IN PLACE UNTIL IMMEDIATELY PRIOR TO MAKING A JOINT IF A CAP HAS BEEN REMOVED FOR LONGER THAN 10 MINUTES PRIOR TO ASSEMBLY THE LINE MUST BE FLUSHED WITH FREON RE CAPPED FITTINGS AND CONNE CTORS PROTEC1 AGAINST DAMAGE TO THE THREAIBI PLASTIC PARTS PROTECT AGAINST STRAINS AND SHOCK DURING ASSEMBLY VALVES THERMOBULB ON EXPANSION VALVES SHALL NOT BE EXPOSED TO TEMPERATURE ABOVE 150 F CARE SHALL BE TAKEN TO PROTECT CAPILLARY TUBES AGAINST ANY BENDING DROPPING OR NICKING THAT MIGHT CAUSE RUPTURE OF THE TUBE CONTROL AND ACTUATING ICNOBS AND LEVERS DO NOT DISTORT IN ANY MANNER SUB ASSEMBLIES ALWAYS GRASP IN SOLID BODY PORTION FOR LIFTING 3 1 1 REJECTED COMPONENTS REJECTED COMPONENTS AND PARTS SHALL BE PROPERLY IDE NTIFIED FOR REASON OF REJE CTION AND SEALED AS NECESSARY WHEN RE TURNED TO THE INSPECTION DEPARTMENTS SALVAGE AREA FOR DIS POSITION 3 1 2 ROTATION OF STOCK STOCK WITH EARLIEST RECEIVING DATE SHALL BE USED FIRST FOR ASSEMBLY OPERATIONS IN ORDER TO KEEP STOCK UP TO DATE 3 2 ASSEMBLY ANY EVIDENCE OF INTERNAL MOISTURE CORROSION OR CONTAMINATION WHEN ASSEMBLIES ARE OPENED FOR INSTALLATION WILL BE REASON FOR REPLACING 3 3 EVACUATION AND CHARGING ALL FITTINGS USED IN EVACUATION AND CHARGING SHALL BE OBSERVED FOR CLEANLINESS 3 3 1 VAPOR CHARGING FROM SHIPPING CYLINDER8 WHEN FREON 12 IS CHARGED DIRECTLY INTO THE CAR SYSTEM FROM THE SHIPPING CYLINDER THE CYLINDER SHALL BE PLACED UPRIGHT ON SCALES FOR PROPER WEIGHING A CONTAINER OF WARM WATER IB RECOMMENDED FOR HEATING THE CYLINDER UNDER NO CIRCUM g STANCES SHALL THE REFRIGERANT CYLINDER BE HEATED ABOVE 125 I S zucazvgoazarj I 0R o vss Gmcq i UPC T sw v s o ec V A AIR CONDITIUNING GENERAL SPECS 1H a PROCEDURES l g wwg 500 Q DwG PR6 7 FM REF Pnl E8 L L I DATERH 2 7 L L L I K3 1 Y 1965 2OO

Next

Next