Jeep Parts Wiki | Ford Parts Wiki

Home | Search | Browse

|

Corvair Chassis Shop Manual December 1964 |

|

Prev

Next

Next

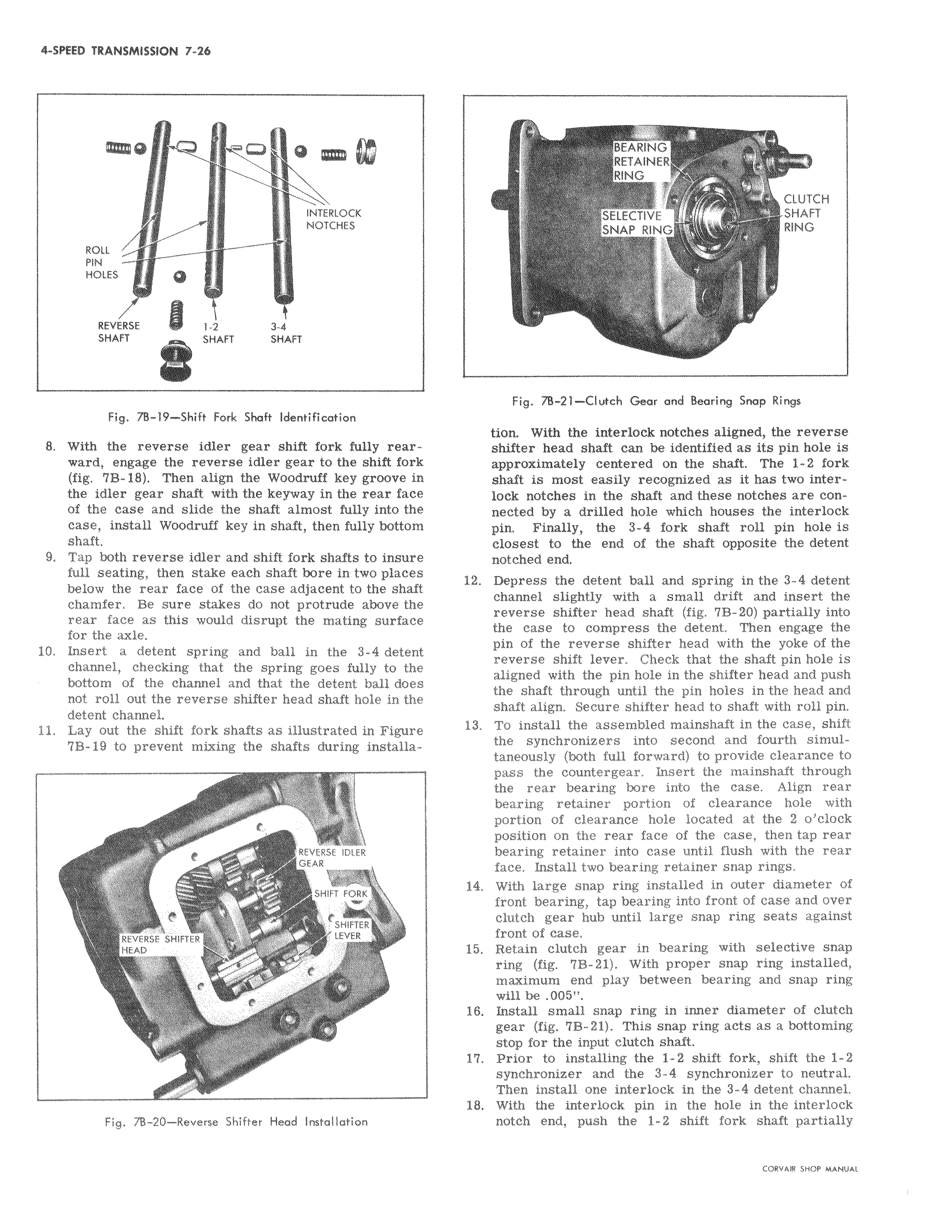

INTERLOCK NOTCHES v v v v r v Fe i W K REVERSE 1 2 3 4 SHAFT SHAFT SHAFT BEARING RETAINE R RING r CLUTCH SELECTIVE SHAFT SNAP RING RING Fig 7B 21 Clutch Gear and Bearing Snap Rings tion With the interlock notches aligned the reverse shifter head shaft can be identified as its pin hole is approximately centered on the shaft The 1 2 fork shaft is most easily recognized as it has two interlock notches in the shaft and these notches are connected by a drilled hole which houses the interlock pin l Finally the 3 4 fork shaft roll pin hole is closest to the end of the shaft opposite the detent notched end 12 Depress the detent ball and spring in the 3 4 detent channel slightly with a small drift and insert the reverse shifter head shaft fig 7B 20 partially into the 1 case to compress the detent Then engage the pin of the reverse shifter head with the yoke of the reverse shift lever Check that the shaft pin hole is aligned with the pin hole in the shifter head and push the shaft through until the pin holes in the head and shaft align Secure shifter head to shaft with roll pin 13 To install the assembled mainshaft in the case shift the synchronizers into second and fourth simultaneously both full forward to provide clearance to pass the countergear Insert the mainshaft through the rear bearing bore into the case Align rear bearing retainer portion of clearance hole with portion of clearance hole located at the 2 o clock position on the rear face of the case then tap rear bearing retainer into case until flush with the rear face Install two bearing retainer snap rings 14 With large snap ring installed in outer diameter of frost bearing tap bearing into front of case and over clutch gear hub until large snap ring seats against front of case 15 Retain clutch gear in bearing with selective snap ring fig 7B 21 With proper snap ring installed maximum end play between bearing and snap ring will be 005 16 Install small snap ring in inner diameter of clutch gear fig 7B 21 This snap ring acts as a bottoming stop for the input clutch shaft 17 Prior to installing the 1 2 shift fork shift the 1 2 synychronizer and the 3 4 synchronizer to neutral Then install one interlock in the 3 4 detent channel 18 With the interlock pin in the hole in the interlock notch end push the 1 2 shift fork shaft partially

Next

Next