Jeep Parts Wiki | Ford Parts Wiki

Home | Search | Browse

|

Corvair Chassis Shop Manual December 1964 |

|

Prev

Next

Next

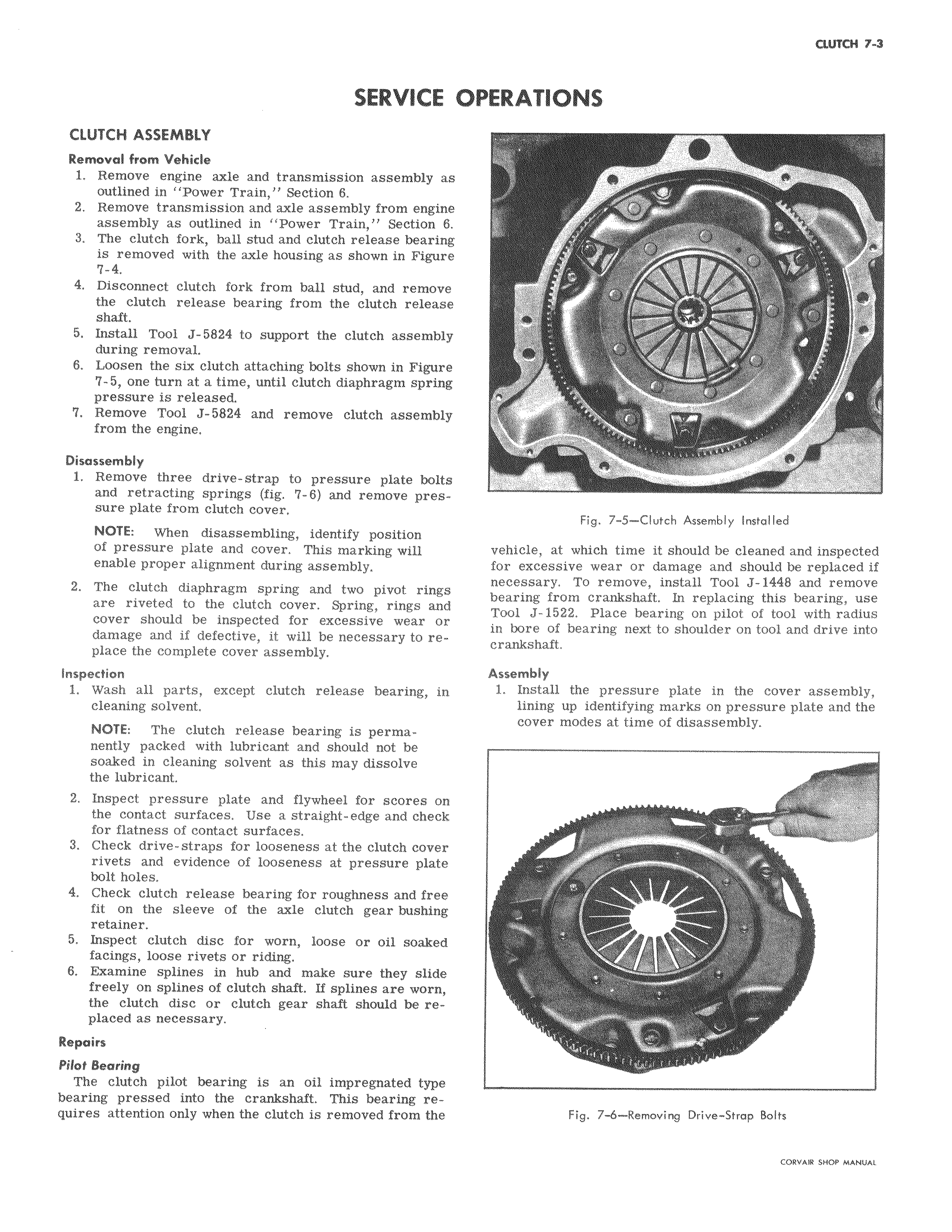

SERVICE CLUTCH ASSEMBLY Removal from Vehicle 1 Remove engine axle and transmission assembly as outlined in Power Train Section 6 2 Remove transmission and axle assembly from engine assembly as outlined in Power Train Section f 3 The clutch fork ball stud and clutch release bearing is removed with the axle housing as shown in Figure 7 4 4 Disconnect clutch fork from ball stud and remove the clutch release bearing from the clutch release shaft 5 Install Tool J 5824 to support the clutch assembly during removal 6 Loosen the six clutch attaching bolts shown in Figure 7 5 one turn at a time until clutch diaphragm spring pressure is released 7 Remove Tool J 5824 and remove clutch assembly from the engine Disassembly 1 Remove three drive strap to pressure plate bolts and retracting springs fig 7 6 and remove pressure plate from clutch cover NOTE When disassembling identify position of pressure plate and cover This marking will enable proper alignment during assembly 2 The clutch diaphragm spring and two pivot rings are riveted to the clutch cover Spring rings and cover should be inspected for excessive wear or damage and if defective it will be necessary to replace the complete cover assembly Inspection 1 Wash all parts except clutch release bearing in cleaning solvent NOTE The clutch release bearing is permanently packed with lubricant and should not be soaked in cleaning solvent as this may dissolve the lubricant 2 Inspect pressure plate and flywheel for scores on the contact surfaces Use a straight edge and check for flatness of contact surfaces 3 Check drive straps for looseness at the clutch cover rivets and evidence of looseness at pressure plate bolt holes 4 Check clutch release bearing for roughness and free fit on the sleeve of the axle clutch gear bushing retainer 5 Inspect clutch disc for worn loose or oil soaked facings loose rivets or riding 6 Examine splines in hub and make sure they slide freely on splines of clutch shaft If splines are worn the clutch disc or clutch gear shaft should be re placed as necessary Repairs Pilot Bearing The clutch pilot bearing is an oil impregnated type bearing pressed into the crankshaft This bearing requires attention only when the clutch is removed from the 7 t a s v v v w v v v a f

Next

Next