Jeep Parts Wiki | Ford Parts Wiki

Home | Search | Browse | Marketplace | Messages | FAQ | Guest

|

Corvair Chassis Shop Manual December 1964 |

|

Prev

Next

Next

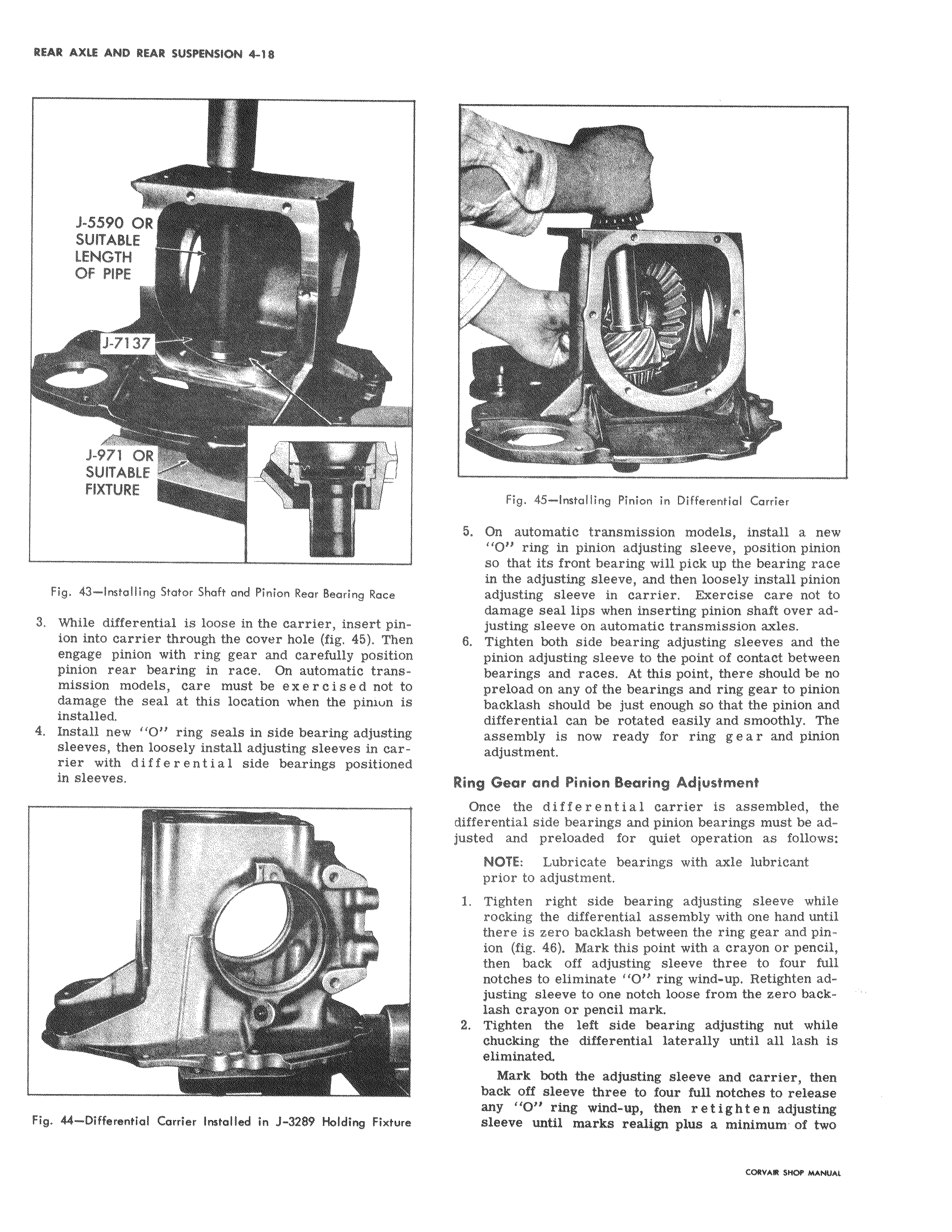

l J 5590 OR SUITABLE LENGTH vx a m W w 1 j J 971 OR SUITABLE FIXTURE r r fil1 45 installing Pinion in Differential Carrier 5 On sLutomatic transmission models install a new O ring in pinion adjusting sleeve position pinion so that its front bearing will pick up the bearing race in the adjusting sleeve and then loosely install pinion adjusting sleeve in carrier Exercise care not to damage seal lips when inserting pinion shaft over adjusting sleeve on automatic transmission axles 6 Tighten both side bearing adjusting sleeves and the pinian adjusting sleeve to the point of contact between bearings and races At this point there should be no prelOad on any of the bearings and ring gear to pinion backlash should be just enough so that the pinion and differential can be rotated easily and smoothly The assembly is now ready for ring g e a r and pinion adjustment Ring Gear and Pinion Bearing Adjustment Once the differential carrier is assembled the differential side bearings and pinion bearings must be adjusted and preloaded for quiet operation as follows NOTE Lubricate bearings with axle lubricant prior to adjustment 1 Tighten right side bearing adjusting sleeve while rocking the differential assembly with one hand until there is zero backlash between the ring gear and pinion fig 46 Mark this point with a crayon or pencil then back off adjusting sleeve three to four full notches to eliminate O ring wind up Retighten adjusti g sleeve to one notch loose from the zero backlash lcrayon or pencil mark 2 Tigh ken the left side bearing adjusting nut while chucking the differential laterally until all lash is elim nated Mirk both the adjusting sleeve and carrier then baclt off sleeve three to four full notches to release any O ring wind up then r e t i g h t e n adjusting sleete until marks realign plus a minimum of two

Next

Next