Jeep Parts Wiki | Ford Parts Wiki

Home | Search | Browse

Prev

Next

Next

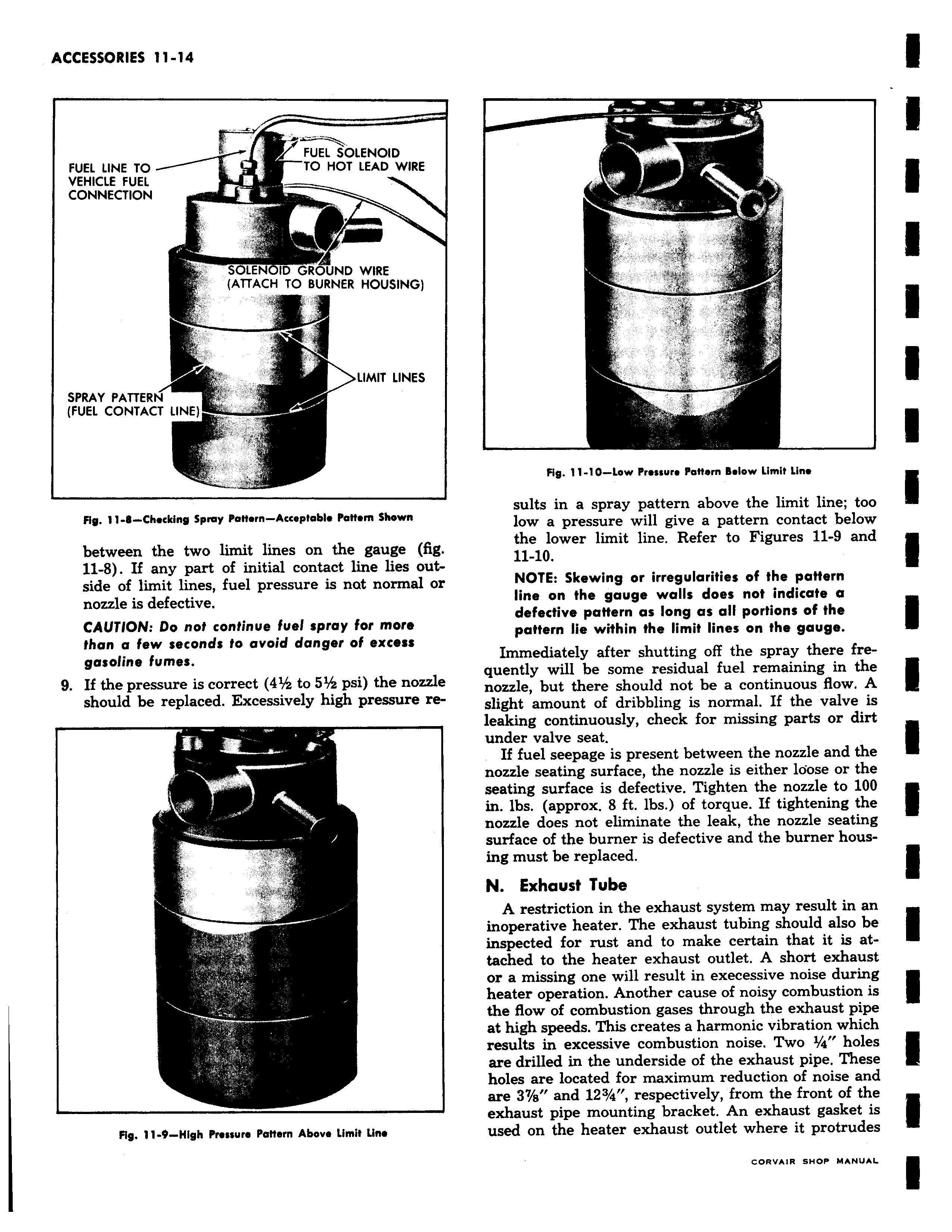

IFA 01 1P M A J 12 Fig 11 A O Low Pressure Pattern Below Limit Line sults in a spray pattern above the limit line too low a pressure will give a pattern contact below the lower limit line Refer to Figures 11 9 and 11 10 NOTE Skewing or irregularities of the pattern line on the gauge walls does not indicate a defective pattern as long as all portions of the pattern lie within the limit lines on the gauge Immediately after shutting off the spray there fre quently will be some residual fuel remaining in the nozzle but there should not be a continuous flow A slight amount of dribbling is normal If the valve is leaking continuously check for missing parts or dirt under valve seat If fuel seepage is present between the nozzle and the nozzle seating surface the nozzle is either Wose or the seating surface is defective Tighten the nozzle to 100 in lbs approx 8 ft lbs of torque If tightening the nozzle does not eliminate the leak the nozzle seating surface of the burner is defective and the burner housing must be replaced N Exhaust Tube A restriction in the exhaust system may result in an inoperative heater The exhaust tubing should also be inspected for rust and to make certain that it is attached to the heater exhaust outlet A short exhaust or a missing one will result in execessive noise during heater operation Another cause of noisy combustion is the flow of combustion gases through the exhaust pipe at high speeds This creates a harmonic vibration which results in excessive combustion noise Two 1 4 holes are drilled in the underside of the exhaust pipe These holes are located for maximum reduction of noise and are 37 8 and 123 4 respectively from the front of the exhaust pipe mounting bracket An exhaust gasket is used on the heater exhaust outlet where it protrudes

Next

Next